*All specifications are approximations and are subject to verification. Comes as shown in the images. Please give us a call if you have any questions before purchasing. All sales are final.*

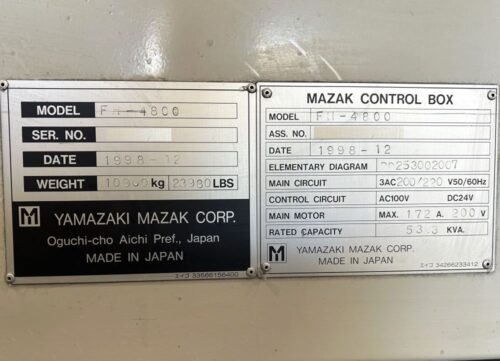

| Make: | Mazak |

| Model No.: | FH-4800 |

| Year of Manufacture: | 12/1998 |

| Equipped With: |

|---|

| Mazatrol 640M PC Fusion CNC Control |

| 12,000 RPM High Precision Spindle |

| Through Spindle Coolant |

| Twin Pallet Changer |

| 80 Station Automatic Tool Changer |

| Renishaw Probing System |

| RS-232 Port |

| Pallet Seat Detection |

| Spindle Orientation |

| Rigid Tapping |

| Fast Rapid Traverse Rate |

| Flood coolant with large coolant tank |

| Chip Conveyor |

| Travels: |

|---|

| X Axis: 560 mm |

| Y Axis: 610 mm |

| Z Axis: 560 |

| B Axis: 1° Indexing (4th Axis) |

| Spindle Nose to Table Center: 150 mm – 710 mm |

| Spindle Center to Table Top: 50 mm – 660 mm |

| Table: |

|---|

| Length: 400 mm |

| Width: 400 mm |

| Max Weight on Table: 400 kg |

| Max Workpiece Diameter: 610 mm |

| Max Workpiece Height: 710 |

| Index Time: seconds |

| Spindle: |

|---|

| Taper Size: 40 |

| Max. Speed: 12,000 RPM |

| Power: 22 kw |

| Feed rates: |

|---|

| Rapid X, Y & Z : 50 Meter Per Minute |

| Cutting Feedrate: 30 Meter Per Minute |

| Automatic Tool changer: |

|---|

| Capacity: 80 Tools |

| Taper: 40 |

| Max Tool Diameter: 150 mm |

| Max Tool Length: 320 mm |

| Max Tool Weight: 12 kg. |

| Tool Change Time: 8 Second |

| General: |

|---|

| Air Required: 90 psi, 4 scfm |

| Power: 53.3 kva / 205-220v / 3-Phase |

| Overall Dimensions: 4090 mm X 2670 mm x 2620 mm High |

| Weight: 10,900 kg. |